How 3D Printing Is Changing the Oil & Gas Industry

The oil and gas industry is a crucial economic sector, yet it faces many difficulties from operating in remote areas. Frequent breakdowns of machinery can create occupational or environmental catastrophes, but sourcing spare parts can be a challenge. Manufacturing often occurs thousands of miles away from drilling sites, resulting in supply chain chokepoints that can spike energy prices for millions. But with the introduction of 3D printing technology to the petrochemical industry, these problems are becoming easier to manage—and the entire industry is transforming as a result.

The attractive benefits of 3D printing are numerous. Printing replacement parts quickly and on-site eliminates costly wait times associated with shipping parts from industrial centers located far away. Furthermore, solving legacy component issues—outdated parts that cannot be manufactured anymore—is made easy with 3D printing technology. And overall extraction processes could become more efficient and cost-effective thanks to 3D printing's fast production capabilities.

Today's article discusses how 3D printing works in the oil and gas industry, and how it affects virtually every part of the industry from top to bottom.

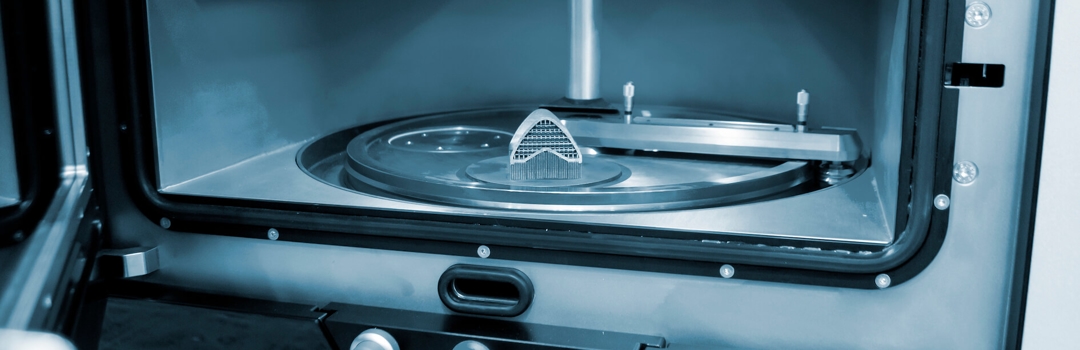

How Does 3D Printing Metal Parts Work?

Metal 3D printing, also known as metal additive manufacturing, is a process of constructing three-dimensional parts from metal powder. The process begins with the build chamber being filled with an inert gas, such as argon, to minimize oxidation. A thin layer of metal powder is spread over the build platform, and it's laser scanned to melt the particles into a single sheet. This process is repeated until the finished part has been built layer by layer. Once complete, any excess powder is removed, and a machinist will cut and machine away the excess material from supports. Supports are made from the same material for stability in high temperatures, preventing warping.

There are different kinds of "powder bed fusion" printing for metals:

- Selective Laser Melting (SLM) for single-metal materials

- Direct Metal Laser Sintering (DMLS) for alloys

- Electron Beam Melting (EBM)

- Ultrasonic Additive Manufacturing (UAM)

Any metal that can be ground into powder and melts at a high temperature can, in theory, be utilized in SLM or DMLS 3D printing.

The main benefit of metal 3D printing is its ability to create complex parts without needing multiple steps or processes. As no machining or tooling is required to create the part, it can be done much faster than traditional methods. Metal 3D printing also allows for more efficient use of materials since only what’s needed is used, so waste can be minimized based on design specifications. It also reduces risk in production because there are fewer steps and less handling involved in making parts compared to traditional methods, which require multiple tools and processes to create a single component.

In addition to speed and efficiency, metal 3D printing provides design freedom that isn't available in traditional manufacturing methods due to its unique layered approach. Additive manufacturing allows for complex shapes and contours that are not achievable via CNC machining or casting. This technology also allows for customization on smaller production runs since each component can be tweaked during manufacture through software manipulation, ensuring accuracy during production without loss of quality or performance. Furthermore, it enables manufacturers to create components using materials that would not be possible using more conventional methods due to their size or shape constraints (such as when attempting to produce small holes in intricate patterns).

All of these benefits have serious implications for the petrochemical industry.

3D Printing Replaces Parts Exponentially Faster

Imagine, for a moment, that your oil rig is located off the coast of Alaska, and you suddenly need a component that's only manufactured in Europe. You're looking at a months-long process of getting that part sourced with traditional manufacturing. First, the manufacturing center needs to be retooled to accommodate the component, which is no longer mass-produced. If there are other high-urgency requests awaiting manufacture, you'll need to wait for those projects to finish before yours is even started; if you can't wait that long, you'll need to pay a hefty premium.

Then you need to get that item through customs, which can be difficult given the regulatory maze the petrochemical industry is subject to. Finally, the part is in your hands—but you'll need to buy space to store all the spares because you didn't just order one; to make sure this never happens again, you ordered enough backup parts to last for decades. From start to finish, you're looking at a months-long process with a years-long investment in inventory space.

With additive manufacturing, the same process takes days—and requires only enough storage space to keep the part's digital file on hand.

By allowing companies to produce parts on-demand, 3D printing can reduce lead times significantly and virtually eliminate the need for storage space. This means that when an operator needs a part quickly, they no longer have to wait weeks or months for the part to be delivered. Instead, they can simply print it themselves onsite with an on-site 3D printer or a local AM center. Furthermore, 3D printing eliminates the cost of capital associated with stocking inventory that may never get used—because only digital files are needed to print parts, there's no need to stockpile physical parts that might not be used anytime soon. In other words, 3D printing offers immense cost savings and efficiency gains throughout the entire supply chain in the oil and gas industry by reducing lead times and storage costs.

3D Printing Revolutionizes Reverse Engineering

But replacing existing parts isn't even the best advantage of printing technology. 3D printing can make reverse engineering custom or legacy parts for oil drilling rigs more efficient than ever before. By using digital designs and 3D scanning, a detailed model and exact measurements of a part can be created from scratch. This digital data can then be used to construct an identical or improved version of the part quickly and accurately without the need for manufacturing instructions.

Unlike traditional manufacturing methods such as CNC machining or casting, additive manufacturing allows engineers to create parts on demand with minimal setup time. With a 3D printer set up in a workshop, all that is needed is the digital data from the scan of the original part. This requires the work of an additive manufacturing specialist who knows how to analyze parts for their 3D printing suitability. Digital data is then fed into a computer-aided design (CAD) software program which generates machine instructions for the printer to create an exact replica.

Using reverse engineering or OEM files, 3D printers can manufacture custom parts of all kinds, including:

- Gas turbine nozzles

- SSD sleeves

- Sand control screens

- Nozzles for downhole cleanup

- Subsea chemical stick injection tool

- Sealing accessories

- Perforated pup joints

- Liner hanger spikes

- Drill bits

- Investment casting patterns

- Fluid/water flow analysis

- Turbomachinery

- Jigs and fixtures

- Rotors

- Stators

- Mud motor modules

- Flowmeter parts

- Pressure gauge pieces

- Control-valve components

- Pump manifolds

- And more.

Additive manufacturing works best when there are no specs available for legacy parts needed for oil drilling rigs that may have been around for decades. It also allows engineers to produce parts quickly and accurately even if they don't have access to replacement parts from their original manufacturer. Reverse engineering new parts through 3D printing reduces downtime caused by or equipment breakdowns.

Reverse engineering also leads to optimization, customization, and improvements for your machinery. Since additive manufacturing technologies are continuously evolving, updated versions of existing designs can easily be produced using sophisticated modeling software and powerful processors with high precision accuracy—meaning higher quality components with greater durability that stand up better to extreme pressure conditions found in deep sea oil drilling rigs.

The Implications of 3D-Printed Parts

Virtually overnight, the entire supply chain for the maintenance and operation of drilling rigs has completely changed. Even the most custom and demanding components for a rig or plant can be produced locally, cutting down significantly on transportation costs and customs delays. The reduced need for parts or materials storage means companies can invest capital elsewhere, making energy cheaper and more efficient to produce. Even the ability to design parts digitally for immediate small-scale production allows engineers to test and simulate new designs, tinkering with old parts to create brand-new components with better performance and higher safety ratings.

The economic implications go beyond oil industry profits. An entire "grey market" of non-OEM parts arose in the last few decades as the availability of OEM parts decreased; with the ability to send digital specs to print almost any component, OEM parts can be made available through any additive manufacturing reseller. Companies looking for 'real' parts are more likely than ever to find them.

Industrial Giants Investing in 3D Printing Already

The petrochemical industry's pivot toward additive manufacturing (AM) isn't just imminent; in many ways, it already happened. Major companies across the oil and gas industry have adopted industrial-scale additive manufacturing capabilities for production. This has enabled them to not only drastically reduce costs but also save labor and capital. For example, in 2013, Baker Hughes developed a new gas turbine from 3D-printed parts, which not only reduced storage costs but also provided a more efficient product.

Shell is another major adopter of AM technology. It has deployed 3D printing across all its sectors as it allows them to produce more complex parts with shorter lead times compared to traditional manufacturing methods. Furthermore, they have been able to reduce material waste while significantly reducing their inventory costs by producing on demand when needed.

Other major petrochemical titans embracing AM methods include:

- GE Oil & Gas

- Siemens Energy

- Halliburton

- Total

- Woodside

Research shows that these investments could be worth up to $32 billion by 2025 and $60 billion by 2030 due to the exponential growth seen in this sector—an enormous boost for the whole industry overall. As much as 83% of oil and gas companies are considering investing or expanding into additive manufacturing technologies, according to a Protolabs survey.

The Risks of Additive Manufacturing for the Oil & Gas Industry

Like with any new technology, the hazards and downsides will need to be explored over time. However, the technology is mature enough that we know some of the basic risks of 3D printing metal parts. Metal additive manufacturing processes release toxic VOCs (volatile organic compounds), which can have serious health consequences. As such, it is absolutely necessary that workers wear proper personal protective equipment (PPE) to protect themselves from potential exposure. In addition, strict guidelines should be put in place to prevent any eating or drinking in the printing environment, as this could lead to contamination if not strictly monitored.

When printing metal parts using a 3D printer, there are several potential dangers that can arise due to the use of metal powder and laser-based processes. Small particles of metal powder can become airborne during the 3D printing process, meaning they can be accidentally inhaled. High-powered lasers are also used during many 3D metal printing processes, meaning there is a risk of explosion or burns if not properly handled. Given the volatile and high-risk environment of an offshore drilling rig, installing a 3D printer could necessitate a whole new set of guidelines specific to printing parts at sea.

At minimum, proper filtration systems and extinguishing devices must be installed in the area where these processes take place. This area should also be designed as a closed environment with controlled ventilation in order to minimize any particulate matter released into the air.

3D printing metal parts presents a number of potential workplace risks that must be taken seriously by all involved workers and employers alike. All safety protocols must be followed rigorously in order to ensure that everyone remains safe while working with this technology—especially when it comes to PPE use and preventing any ingestion or inhalation of potentially harmful substances released during the process.

New Horizons Bring New Opportunities...& New Dangers

In Iron Man (2008), the protagonist digitally designs a groundbreaking piece of tech, then tells his computer to manufacture it to spec while he walks away. Only 15 years later, that may become the truth of how oil rigs create new or replacement parts.

It's clear that 3D printing has opened up new possibilities for the petrochemical industry: it not only helps reduce downtime through quick repairs, but also reduces costs associated with sourcing replacement parts from remote locations. Moreover, the use of this innovative technology allows for better monitoring of equipment operations via data logging capabilities built into 3D printed components. Finally, by localizing manufacturing processes to drilling sites instead of sending raw materials back and forth between industrial centers and on-site facilities, producers can achieve an even greater level of efficiency in their operations.

3D printing provides an incredibly versatile solution to many problems faced by the petrochemical industry—from reducing downtime due to repairing broken machinery to eliminating costly supply chain chokepoints caused by sourcing spare parts from remote locations. With its broad range of advantages over traditional manufacturing methods, it's no wonder why this revolutionary technology is taking over the petrochemical sector. However, with new opportunities come new hazards. It's up to employers and rig owners to ensure the cost-savings of 3D printing are reinvested into ensuring the safety and well-being of the crew.

The price of doing otherwise is too steep.